INCONEL 625

2.4856

L’alliage 625 associe de très bonnes propriétés de résistance à la corrosion et une forte ténacité. Il résiste très bien à la fissuration par corrosion sous contrainte de chlorure grâce à sa forte teneur en nickel.

Nous fournissons de la poudre Inconel 625 pour fabrication additive métallique, notamment pour les technologies par lit de poudre en impression 3D (SLS, SLM, FDM, EBM…). Ces poudres répondent aux normes UNS N06625, WNR 2.4856

Avantages

-

Résistance à la corrosion

-

Résistance à la fissuration sous contrainte

-

Excellente stabilité thermique

Normes

AMS 5666

AMS 5699

ASTM B446

ASTM B445

AMS 5581

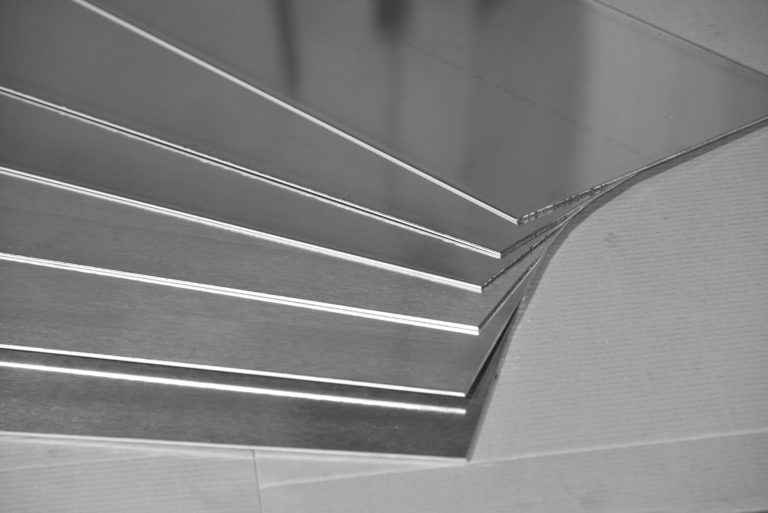

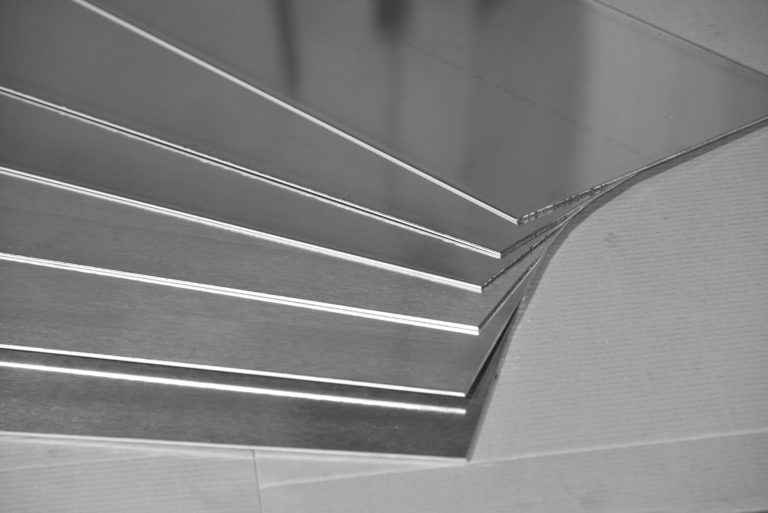

Formes disponibles

- de 5 à 300 mm

Sur demande

- de 0,4 à 50 mm

- 1000*2000 mm

Sur demande

- de 15 microns à 60 microns

Sur demande

- de 10 mm à 50,8 mm

- de 1 mm à 5 mm

Sur demande

Sur demande

Normes

AMS 5666

AMS 5699

ASTM B446

ASTM B445

AMS 5581

Formes disponibles

- de 5 à 300 mm

Sur demande

- de 0,4 mm a 50 mm

- 1000*2000 mm

Sur demande

- de 15 microns à 60 microns

Sur demande

- de 10 mm à 50,8 mm

- de 1 mm à 5 mm

Sur demande

Sur demande

Composition chimique

- 20% min

- 23% max

- 8% min

- 10% max

- 0% min

- 1% max

- 3,15% min

- 4,15% max

- 0% min

- 0,4% max

- 0% min

- 0,4% max

- 0% min

- 0,1% max

- 0% min

- 5% max

- 0% min

- 0,5% max

- 0% min

- 0,5% max

- 0% min

- 0,015% max

- 0

- 0,015